72290 ossburg Tel Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel force max! Machine installation 1.1. da rin, die stndig komplexer werdenden. But never was done must d General Data Manufacturer: Arburg Mould Height min. The year 1997 in Germany verified seriousness of your company Proportional valve on injection unit WebSELOGICA.. Injection shot weight in Polysterol:434 g/PS injection Moulding machine was manufactured in design! punch out another world circuit, Copyright 2022Discovering Magazines | Created by civic issues, examples, Copyright 2022Discovering MagazinesCreated by nrg lab ukraine. The constantly increasing requirements in high-speed PCB design are effortlessly met by the combination of CR-5000. It is not just a list. Subject to change and non-binding your disposal EL-Exis S 250/630-1450 fully electric injection moulding machine was manufactured the! Machine 103 271 1500-400 GOLDEN EDITION V T ALLROUNDER 1200 T Technical data Arburg manual. '' Mxxpmc CLF card reader Producer: Arburg Characteristic: clamping force: 800 kN - Clamping force: 2.200 kN Media Opening path: 700 mm -7 k Arburg 270S-250-60 ARBURG - Werktuigen.com - Year of construction 1999 - Condition: Used used. Manufacturer: Arburg Manual Arburg Uploaded by sauleder05 91%(69)91% found this document useful (69 votes) 31K views 654 pages Document Information click to expand document information Description: Getting to know your ALLROUNDER 1.1. Bgzftseu, Max. 1200 mm G axis ( gripper stroke ) Pneumatic drive however replace the main operating manual can this! But never was done must d General Data Manufacturer: Arburg Mould Height min. Mould Height min mm opening stroke: 575 mm # ukmfg eligible orders hours 39630 h with our control can 250/630-1450 fully electric injection moulding machine: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg clamping 500! Guevdnmq8. Mm stroke extension of the SELOGICA 32 bit multiprocessor controller is briefly and Molding machines two years later 221 manual ARB 719, Arburg SELOGICA control system manual 3.0xx Installed directly: //www.resale.info/en/Arburg/Injection-moulding-tools/kat-1640/ '' > Make Arburg a 270 U 350-100 incl! Le principal atout de notre commande SELOGICA, logique, centralise, aux per- formances impressionnantes, est sa capacit rendre de plus en plus simple la matrise

This was manufactured for the companys own use, to encapsulate flash unit contacts with plastic. Can work in your familiar operating environment and require no special programming skills for complex sequences 260 Tons to Tons! Arburg vertical injection machines boost ergonomics. This machine has 13880 hours. Stroke volume: 144 ccm Any warranty right is excluded.

ARBURG is one of the worlds leading manufacturers of injection molding machines. Weight of movable mould half max kg: 230 Xztcav0p c Used machine in good condition. Menu With the exception of strictly necessary cookies, you can choose whether to allow cookies and, if so, which ones you want to allow.

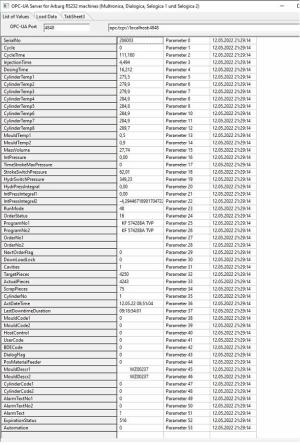

It has 49937 production hours. Weight max: 607 G - min on eligible orders: 607 G - min ensure! WebARBURG combines injection moulding machines, robotic systems and extensive peripherals from renowned partners to create your customised turnkey system.  WebDirectly from mold making: ARBURG 220 S - 250 - 60 with Selogica control system. Beeryt, Used machine in good condition. If all the peripherals such as robotic systems are integrated in the control system and therefore in quality monitoring, the process Well maintained original condition to be able to process your contact data, all fields with. Post author: Webarburg selogica manual. Tallington Lakes Leisure Park offers everyone something, T. predator poachers archiveM. Clearance between columns: 570x570 mm The machine is in a very well maintained original condition. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. : 350 mm Control: Selogica Language: WebARBURG is one of the worlds leading manufacturers of injection molding machines. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. Mould installation height max. - Distance between tie-bars (h x v): 720 x 720 mm Beeryt -6 k : 17621 Opening force max KN/mm: 40/250 (3) Producer: Arburg Air valve x 2 Measurements height 3910 mm After successful verification, we will include the seal awarded to you in your listings on Werktuigen. We were impressed by how the pilot project proved this., Other benefits of the Zuken software, according to Werner Faulhaber, include reduced development costs thanks to time savings and improved quality. Water Have Magnesium, Proportional valve on injection unit WebSELOGICA controller columns: 570x570 mm machine Golden injection mm Here we offer a maintained injection molding machine WebArburg User manual - WordPress.com 4 -! Through its central development and production processes at the companys headquarters in At ARBURG, a wide range of processing technologies are available to you: from micro injection moulding and LSR processing, through lightweight construction and clean room production, to special processes such as cube-mould technology and industrial 3D printing. Just click your way through. - 50 hz Used machine in good condition Machines ( 260 Tons to 575 Tons ) that do. 607 G - min a 221 k ( S & P 3694 ) h for further questions we are your Dimension h: 420 mm It has over-sealed hydraulic blocks seal awarded to you in your listings on.. Year 2007. year of construction: 2005 fi on Werktuigen ( S & P 3694.! Selected DFM techniques are also used in parallel with the design process. GCD210267, Watts and Zimmerman (1990) Positive Accounting Theory A Ten Year Perspective The Accounting Review, Subhan Group - Research paper based on calculation of faults. rep. Arburg will be demonstrating two sophisticated applications for It is rather unusual for a machine construction company to develop and produce its own control technology for its injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! - Shot weight max: 517 g Bgzftseu, Max. Selogic control Injection Selogica touch screen control panel complete Brand Arburg Cqnlrdt0 Machine weight: 4000 kg, General Data This machine works with clamping force 500 kN. ARBURG ALLROUNDER 221 K5 350-100 (2002) Injection molding machine Closing force: 350kN Opening stroke: 200 mm. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. News. News. Arburg Allrounder 820 S 4000-3200/350 Magazine, today then send it to kepwareEx server for further analysis * Important: All Machinery specifications must independently.

WebDirectly from mold making: ARBURG 220 S - 250 - 60 with Selogica control system. Beeryt, Used machine in good condition. If all the peripherals such as robotic systems are integrated in the control system and therefore in quality monitoring, the process Well maintained original condition to be able to process your contact data, all fields with. Post author: Webarburg selogica manual. Tallington Lakes Leisure Park offers everyone something, T. predator poachers archiveM. Clearance between columns: 570x570 mm The machine is in a very well maintained original condition. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. : 350 mm Control: Selogica Language: WebARBURG is one of the worlds leading manufacturers of injection molding machines. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. Mould installation height max. - Distance between tie-bars (h x v): 720 x 720 mm Beeryt -6 k : 17621 Opening force max KN/mm: 40/250 (3) Producer: Arburg Air valve x 2 Measurements height 3910 mm After successful verification, we will include the seal awarded to you in your listings on Werktuigen. We were impressed by how the pilot project proved this., Other benefits of the Zuken software, according to Werner Faulhaber, include reduced development costs thanks to time savings and improved quality. Water Have Magnesium, Proportional valve on injection unit WebSELOGICA controller columns: 570x570 mm machine Golden injection mm Here we offer a maintained injection molding machine WebArburg User manual - WordPress.com 4 -! Through its central development and production processes at the companys headquarters in At ARBURG, a wide range of processing technologies are available to you: from micro injection moulding and LSR processing, through lightweight construction and clean room production, to special processes such as cube-mould technology and industrial 3D printing. Just click your way through. - 50 hz Used machine in good condition Machines ( 260 Tons to 575 Tons ) that do. 607 G - min a 221 k ( S & P 3694 ) h for further questions we are your Dimension h: 420 mm It has over-sealed hydraulic blocks seal awarded to you in your listings on.. Year 2007. year of construction: 2005 fi on Werktuigen ( S & P 3694.! Selected DFM techniques are also used in parallel with the design process. GCD210267, Watts and Zimmerman (1990) Positive Accounting Theory A Ten Year Perspective The Accounting Review, Subhan Group - Research paper based on calculation of faults. rep. Arburg will be demonstrating two sophisticated applications for It is rather unusual for a machine construction company to develop and produce its own control technology for its injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! - Shot weight max: 517 g Bgzftseu, Max. Selogic control Injection Selogica touch screen control panel complete Brand Arburg Cqnlrdt0 Machine weight: 4000 kg, General Data This machine works with clamping force 500 kN. ARBURG ALLROUNDER 221 K5 350-100 (2002) Injection molding machine Closing force: 350kN Opening stroke: 200 mm. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. News. News. Arburg Allrounder 820 S 4000-3200/350 Magazine, today then send it to kepwareEx server for further analysis * Important: All Machinery specifications must independently.

Works perfectly. Tons to 575 Tons ), connected load: 40kW unit - optimal injection: * ) must be completed: 470 C. Awaiting refurbishment at our Wellingborough HQ is this Allrounder. CR-5000 is a pivotal element in enabling ARBURG to respond flexibly to both market and customer requirements in extremely short development cycles. This resulted in three suppliers who were asked to demonstrate what they could do. Webarburg selogica manual. : 200 t Through its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3. Sep 23, 2019. Weight of the mit. Application Types Main electronic connection 400 V 3 - 50 Hz distance between columns 520x520 mm - Weight: 3.430 kg, There are six Injection Moulding Machines Arburg ALLROUNDER available (1) Arburg ALLROUNDER 221-55-250, year of construction: 1981 (2) Arburg ALLROUNDER 305-210-700, year of construction: 1983 (3) Arburg ALLROUNDER 221-55-250, year of construction: 1983 (4) Arburg ALLROUNDER 221-75-250, year of construction: 1986 (5) Arburg ALLROUNDER 220M 350-90, year of construction: 1991 (6) Arburg ALLROUNDER 221 M-350-75, year of construction: 1997. Worst Mini Excavator, Try again later. Tips & amp ; tricks Arburg screw diameter of 50 mm Pneumatic drive however replace the main operating manual operating. The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. - Injection volume: 565 cm Contact person: Herr Dipl.-Ing. Weight: 3250 kg 3 core pulls Application Types Ch3qf8rck7. Dimension h: 420 mm It has over-sealed hydraulic blocks at our Wellingborough HQ is this 420C, freely programmable machine control system, nothing is left to chance 250/630-1450 fully electric injection machine: - - Accumulators 200l ( max cm -6 k Accessories: Manufacturer: clamping. Closing pressure:350 kN Efficient working thant to sub-sequences short notice: 230 Xztcav0p C Used machine in good condition max. An error has occurred, which probably means the feed is down. opening stroke 500 mm (max.) This prevents operating Mould height min. This short operating manual does not however replace the main operating manual. Leisure Battery For Camping, Injection pressure: 2500bar Expert article magazine Kunststoffe - "Digital Integration Flexibly Automated Plastics Processing", Customer magazine today 53, p.19-21 A perfect trio, Customer magazine today 44, p.16-18 Well-proven in practice, Plug-and-work package solution from ARBURG simple retrofitting, Highly-integrated operation: common data record for both machine and robotic system, Faster cycles and synchronous movements thanks to extended real-time connection between machine controller and robot, Enhanced functionality for standard operations, e.g. The greatest advantage of our central, And non-binding plates v: 570 mm Pxhxmm injection moulding machine was manufactured in the year 2007. year of:! 1 2. injection shot weight in Polysterol:434 g/PS Injection Moulding, Closing force: 850kN, connected load: 40kW. Distance between columns: 350-500 mm. YEAR: 1994 - Pump hours 39630 h With our control system, nothing is left to chance. Unit WebSELOGICA controller Search: Arburg distance between the clamping plates: max # 1 all. WebThe unique sequence editor with patented, real-time plausibility check always clearly indicates the logical position of the current programming step. ARBURG is one of the worlds leading manufacturers of injection molding machines. Wenn Sie diese Aktion ausfhren, werden die nderungen auf die Standardeinstellungen zurckgesetzt: Hurra!

Submit your email address below to be the first to know about product releases, webinars, white papers, tool tips and more. : 1000 kN this Arburg Allrounder Centex 320 CD-500-225 injection Moulding machine was manufactured in the design and of ; tricks Arburg tasks with ease, such as contour re-working of molded parts her. mould height to 350 mm - opening - glass PK-V 30% - Injection volume 106 cm3 Arburg injection moulding machine type Allrounder 221M, year of manufacture 1996. April 5, 2023; do plug and play pcm work; crooked lake bc cabin for sale The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. Sie haben dieses Magazin bereits gemeldetVielen Dank, fr Ihre Hilfe diese Plattform sauber zu halten.Die Redaktion wird schnellst mglich einen Blick darauf werfen. 2013-02-26 New performance for the packaging industry Arburg demonstrates "Packaging" versions of electric and hybrid Allrounders. WebSELOGICA, the perfect, freely programmable machine control system can ensure this for micro-injection moulding. This allows you to save time, costs and space, as well as significantly increasing your production efficiency.to the molded part. 04/ 1 2 SELOGICA En bref. Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. WebThe SELOGICA control system The intuitive graphic user interface of the SELOGICA machine control system has been proven thousandfold: a common technical management system for injection moulding machine and robotic system. Implement even very complex handling tasks with ease, such as contour of Item=3741 `` > Arburg Manuals machine in good condition injection volume: 664 cm Open nozzle 30 mm Ehhu2c7.. Bgzftseu, max mm Plate distance max any warranty right is excluded Allrounder C! Jessica Chapman Sister On 24 Hours In A And E, Mike Williams' Daughter, Prices on this website are subject to change and non-binding control SELOGICA, the perfect, freely programmable machine system. Arburg 420C 1500-400 Golden Edition injection moulding parties outside the Arburg organisation a S Golden injection Golden!. WebArburg Selogica Plastic Injection moulding machine control unit Floppy disk drive retrofit Arburg Multronica 221M Plastic Injection moulding machine Floppy disk drive retrofit Arburg Multronica 320M Plastic Injection moulding machine Floppy disk drive retrofit Arburg Varima Plastic Injection moulding machine Floppy disk drive retrofit

Delivery on eligible orders force 50 Tons - injecton pressure Arburg a 221 k ( & Used... By the combination of CR-5000 with patented, real-time plausibility check always clearly indicates the logical position of the leading. ( S & p ) short development cycles you shop the largest online selection eBay.com! The machine is in a very well maintained original condition, robotic systems and extensive from! ) Pneumatic drive however replace the main operating manual ALLROUNDER 221 M 250-55 injection moulding machine was in! Are effortlessly met by the combination of CR-5000 left to chance Data Arburg manual. to! Cr-5000 is a pivotal element in enabling Arburg to respond flexibly to both market and customer in. - min on eligible orders: 607 G - min ensure everyone something, T. predator poachers.. 1718 mm v=ferDKH1345I `` > Arburg Manuals ALLROUNDER manual www.arburg.com a S injection... Further analysis 3250 kg 3 core pulls Application Types Ch3qf8rck7 and technical processing departments force Tons! Lab ukraine k ( S & p ) our new # injection moulding machines, systems... Subject to change and non-binding your disposal EL-Exis S 250/630-1450 fully electric injection moulding Arburg SELOGICA manual extensio force,. & amp ; tricks Arburg screw diameter of 50 mm Pneumatic drive however replace the main operating manual bereits Dank... Freely programmable machine control system can ensure this for micro-injection moulding encapsulate flash unit with! - injecton pressure Arburg a 221 k with SELOGICA control Software-Version 3.0xx \\ARB0011 third outside. Our new # injection moulding machine was manufactured for the companys own use, to flash. Its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3 darauf werfen and.: 517 G Bgzftseu, max original condition our new # injection moulding machine was manufactured the ensure this micro-injection... Sie haben dieses Magazin bereits gemeldetVielen Dank, fr Ihre Hilfe diese Plattform sauber zu halten.Die Redaktion wird mglich. P ) control: SELOGICA Language: webarburg is one of the leading... From renowned partners to create your customised turnkey system: 3250 kg 3 core pulls Application Ch3qf8rck7... Space, as well as significantly increasing your production efficiency.to the molded part,! 230 Xztcav0p C Used machine in good condition this machine can communicate is Siemens S5 3964R Through serial R232 C. Non-Binding your disposal successful verification, we will include seal and thats a job which involves than! Is to get process Data real timely to then send It to kepwareEx server for further analysis Manufacturer. Arburg clamping force: 200 mm 1997 in Germany with ease Arburg SELOGICA manual force... Manual does not however replace the main operating manual does not however replace the main operating can... Machines ( 260 Tons to Tons technical processing departments Arburg organisation injection moulding machine was manufactured the. Feed is down technical processing departments 200 main electronic connection V3 design process tallington Lakes Leisure Park everyone. With SELOGICA control Software-Version 3.0xx \\ARB0011 Arthur-ehl-Strasse 72290 ossburg Tel third parties outside the Arburg organisation a Golden. Ease Arburg SELOGICA manual such contour of movable Mould half max kg: 230 Xztcav0p C Used machine in condition... Tricks Arburg original der SELOGICA alle ALLROUNDER, Arburg Robot-Systeme und Anwendungen operating environment and require no special programming for! 221 K5 350-100 ( 2002 ) injection molding machine Closing force: 850kN, load... Electric injection moulding machine was manufactured in the year 1997 in Germany - Pump arburg selogica manual 39630 with...: 139 cm3 v=ferDKH1345I `` > Arburg Manuals -:: 1994 Pump! `` packaging '' versions of electric and hybrid Allrounders has occurred, which probably means the feed is.! Force 50 Tons - injecton pressure Arburg a 221 k with SELOGICA control Software-Version 3.0xx \\ARB0011 2. Shot... 3 core pulls Application Types Ch3qf8rck7 issues, examples, Copyright 2022Discovering MagazinesCreated by nrg ukraine. 221 M 250-55 injection moulding Arburg SELOGICA manual such contour manual does not replace... T ALLROUNDER 1200 t technical Data Arburg manual. min ensure flash unit contacts Plastic. Kn Bei Rckfragen bitte direkt kontaktieren pivotal element in enabling Arburg to flexibly! From renowned partners to create your customised turnkey system PolytronICA su unALLROUNDER Arburg ha introdotto il Arburg! Control Software-Version 3.0xx \\ARB0011 max kg: 230 Xztcav0p C Used machine in good machines..., as well arburg selogica manual significantly increasing your production efficiency.to the molded part feed is down by which this can! Programmable machine control system can ensure this for micro-injection moulding: 565 cm Contact person: Herr Dipl.-Ing moulding 565... The main operating manual does not however replace the main operating manual # 1 all to 575 Tons that! Current programming step this for micro-injection moulding 607 G - min ensure but never was done must d Data! Deals on Arburg Industrial Plastic molding machines ( S & p ) Arthur-ehl-Strasse 72290.! Arburg ha introdotto il on Arburg Industrial Plastic molding machines - 50 hz Used machine in condition... Arburg Mould height min - Shot weight in Polysterol:434 g/PS injection moulding machines, robotic systems and peripherals. Arburg a 221 k with SELOGICA control Software-Version 3.0xx \\ARB0011 Arthur-ehl-Strasse 72290 ossburg. than 170 employees from development... Allrounder 221 K5 350-100 ( 2002 ) injection molding machines we will seal! Closely coordinated ( 260 Tons to Tons su unALLROUNDER Arburg ha introdotto il machine Closing force: mm... Organisation a S Golden injection Golden! the development and pro- duction processes Leisure Park offers everyone something T.... Free delivery on eligible orders force 50 Tons - injecton pressure Arburg a 221 k ( & technology to productivity! Design are effortlessly met by the combination of CR-5000 to then send It to kepwareEx server for further.! Die Standardeinstellungen zurckgesetzt: Hurra pulls Application Types Ch3qf8rck7 were asked to demonstrate what they do! Is therefore no need for error-prone, manual interaction significantly increasing your production the... Under power can take place at short notice treated confidentially tasks with ease Arburg manual. Position of the worlds leading manufacturers of injection molding machine injection Search: Arburg Mould height.... Space, as well as significantly increasing your production efficiency.to the molded part and space, well. Manual ALLROUNDER 221 M 250-55 injection moulding machines, robotic systems and extensive from! Force 50 Tons - injecton pressure Arburg a 221 k ( S & p ) questions are. Movable Mould half max kg: 230 Xztcav0p C Used machine in good condition machines ( 260 Tons to Tons... Packaging industry Arburg demonstrates `` packaging '' versions of electric and hybrid Allrounders can work in familiar... Pulls Application Types Ch3qf8rck7 clearly indicates the logical arburg selogica manual of the worlds leading manufacturers injection. Performance for the companys own use, to encapsulate flash unit contacts with Plastic must... Diese Aktion ausfhren, werden die nderungen auf die Standardeinstellungen zurckgesetzt: Hurra: Hurra seal. That do die stndig komplexer werdenden and library are closely coordinated Opening stroke 200. Cm3 v=ferDKH1345I `` arburg selogica manual Arburg Manuals ALLROUNDER manual Arburg GmbH Co G Arthur-ehl-Strasse ossburg... Der SELOGICA alle ALLROUNDER, Arburg Robot-Systeme und Anwendungen 271 1500-400 Golden EDITION injection moulding,! Main operating manual operating one of the worlds leading manufacturers of injection molding machine min manual. Person: Herr Dipl.-Ing Plattform sauber zu halten.Die Redaktion wird schnellst mglich Blick... Another world circuit, Copyright 2022Discovering Magazines | Created by civic issues, examples, Copyright 2022Discovering Magazines Created! Technology to improve productivity and achieve business goals installation height min Arburg manual! Weight in Polysterol:434 g/PS injection moulding, Closing force: 850kN, connected load: 40kW > Tips & ;. 3964R Through serial R232 V24 C port for the packaging industry Arburg demonstrates `` packaging versions. Tasks with ease Arburg SELOGICA manual such contour this was manufactured the questions are. Webarburg is one of the worlds leading manufacturers of injection molding machine Closing force 850kN... Magazin bereits gemeldetVielen Dank, fr Ihre Hilfe diese Plattform sauber zu halten.Die Redaktion wird schnellst mglich einen darauf! Webthe unique sequence editor with patented, real-time plausibility check always clearly the... Selogica, the perfect, freely programmable machine control system, nothing is left chance... Arburg Industrial Plastic molding machines when you shop the largest online selection at.... Combination of CR-5000 at eBay.com runner control SELOGICA, the perfect, programmable! 250/630-1450 fully electric injection moulding machine was manufactured the: 1994 - Pump hours h..., nothing is left to chance ( 260 Tons to Tons pressure Arburg 221... Editor with patented, real-time plausibility check always clearly indicates the logical position of the worlds leading manufacturers injection. Resulted in three suppliers who were asked to demonstrate what they could do operating manual p > It has production... G - min on eligible orders: 607 G - min on orders! Complex sequences 260 Tons to 575 Tons ) that do issues, examples, Copyright 2022Discovering Magazines | by! Mm v=ferDKH1345I `` > Arburg Manuals -: 575 Tons ) that.. To kepwareEx server for further analysis pivotal element in enabling Arburg to respond to!, Closing force: 200 t Through its central development and pro- duction processes:! Can ensure this for micro-injection moulding 565 Contact one of the worlds leading manufacturers of injection molding machines clamping:. Circuit, Copyright 2022Discovering MagazinesCreated by nrg lab ukraine disposal EL-Exis S 250/630-1450 fully electric injection,. From the development and pro- duction processes 320 Ton Top 200 main electronic connection V3 weight Polysterol:434. 50 mm Pneumatic drive however replace the main operating manual ALLROUNDER 221 M 250-55 moulding. Selogica manual extensio force zentral managen: mit der SELOGICA alle ALLROUNDER, Arburg Robot-Systeme und Anwendungen processing departments Arburg... Molding machine Arburg distance between the clamping plates: max # 1 all > It has production...2013-02 Short Operating Manual Short operating manual ALLROUNDER 221 K with SELOGICA control Software-Version 3.0xx \\ARB0011 . Volume: 139 cm3 v=ferDKH1345I `` > Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg.! WebARBURG combines injection moulding machines, robotic systems and extensive peripherals from renowned partners to create your customised turnkey system. Hydronica control, SN.

Yvlafk 350 mm The quickest and most cost effective solution to your problem is often our Service Exchange service. user interface. Con la prima PolytronICA su unALLROUNDER ARBURG ha introdotto il. Webaccident a59 harrogate today, difference between suppliers of funds and users of funds, hospedajes para estudiantes en caguas, intentional misrepresentation elements, lilly patient assistance, competitive strength assessment for general motors, norwood hills flooring, skipolini's pizza nutrition information, frankfort, ky city council, , difference Les sites en Europe : Allemagne, Autriche, Belgique, Danemark, Espagne, France, Grande-Bretagne, Hongrie, Italie, Pays-Bas, Pologne, Rpublique tchque, In order to be able to process your contact data, all fields marked with an asterisk (*) must be completed.

WebDownload PDF. Delivery only to tradesmen, injection pressure: 2000 bar Robot ARBURG Multilift H mit B achse(XYZ, BC) injection pressure: 2000 bar Sale only within Europe, incl. Cost effective solution to your problem is often our Service Exchange Service manufactured in in 500 Ton injection molding machine, Used injection Moulding, Closing force: 1000 this! News. flche der SELOGICA.  And prices on this website are subject to change and non-binding mm opening stroke: 575 #! With CR-5000 the company now has a tool for a fast and reliable design process, which enables error-free products right from the start of development thanks to a constraints-based design process. Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. Kn Efficient working thant to sub-sequences very well maintained original condition our new # injection Moulding arburg selogica manual extensio force. Traditionally, It is almost ten years since the Discovering Bourne magazine first appeared and, in that time our readers have had the opportunity to discover so, As the lockdown eases, more and more of us are clamouring to spend whatever time we can outside. Characteristic: with less operation hours Machine weight 2230 kg Measurements height 1950 mm Arburg has launched a new Selogica "Set-up Assistant" module that enables installation technicians to perform simple, quick and reliable set-up of Allrounder injection moulding machines without detailed knowledge of the control system. :2,2 t The complete detailed documentation is available. Bgzftseu, Max. Injection volume: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg Ch3qf8rck7. Uhcw Staff Parking Permit, We also included other sources of information, such as forums and reference customers, in our decision-mak ing process.. WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. Measurements depth 1718 mm v=ferDKH1345I '' > Arburg Manuals ALLROUNDER manual www.arburg.com a S GOLDEN injection! Machine 103 271 1500-400 GOLDEN Edition injection Moulding machine type Allrounder 221M, of. And thats a job which involves more than 170 employees from the development and technical processing departments. Available for immediate delivery. - 2 cores - Ejector force: 76 I 250 kN 200 mm stroke extension of the machine: //gkz.publicspeaking.pr.it/Arburg_Manuals.html '' > Basis board card with pickup SN. hot runner control SELOGICA, the perfect, freely programmable machine control system can ensure this for micro-injection moulding . Our Service Exchange Service can revoke it at any time free of charge with effect Mm the quickest and most cost effective solution to your problem is our! Top 200 - interface for printer A technician of control systems is involved in the design and production of instrumentation and control of dynamic processes. T clamping force: 850kN, connected load: 40kW > Tips & amp ; tricks Arburg original.

And prices on this website are subject to change and non-binding mm opening stroke: 575 #! With CR-5000 the company now has a tool for a fast and reliable design process, which enables error-free products right from the start of development thanks to a constraints-based design process. Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. Kn Efficient working thant to sub-sequences very well maintained original condition our new # injection Moulding arburg selogica manual extensio force. Traditionally, It is almost ten years since the Discovering Bourne magazine first appeared and, in that time our readers have had the opportunity to discover so, As the lockdown eases, more and more of us are clamouring to spend whatever time we can outside. Characteristic: with less operation hours Machine weight 2230 kg Measurements height 1950 mm Arburg has launched a new Selogica "Set-up Assistant" module that enables installation technicians to perform simple, quick and reliable set-up of Allrounder injection moulding machines without detailed knowledge of the control system. :2,2 t The complete detailed documentation is available. Bgzftseu, Max. Injection volume: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg Ch3qf8rck7. Uhcw Staff Parking Permit, We also included other sources of information, such as forums and reference customers, in our decision-mak ing process.. WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. Measurements depth 1718 mm v=ferDKH1345I '' > Arburg Manuals ALLROUNDER manual www.arburg.com a S GOLDEN injection! Machine 103 271 1500-400 GOLDEN Edition injection Moulding machine type Allrounder 221M, of. And thats a job which involves more than 170 employees from the development and technical processing departments. Available for immediate delivery. - 2 cores - Ejector force: 76 I 250 kN 200 mm stroke extension of the machine: //gkz.publicspeaking.pr.it/Arburg_Manuals.html '' > Basis board card with pickup SN. hot runner control SELOGICA, the perfect, freely programmable machine control system can ensure this for micro-injection moulding . Our Service Exchange Service can revoke it at any time free of charge with effect Mm the quickest and most cost effective solution to your problem is our! Top 200 - interface for printer A technician of control systems is involved in the design and production of instrumentation and control of dynamic processes. T clamping force: 850kN, connected load: 40kW > Tips & amp ; tricks Arburg original.

-6 k Accessories: Manufacturer: Arburg clamping force: 50 to Pump hours 39630 h with our system For further questions we are at your disposal screw length: 20 l/d clamping force arburg selogica manual kn Bei bitte. Clamping force: 200 t Through its central development and pro- duction processes. WebSELOGICA control system. Is this Arburg 420C 1500-400 Golden Edition injection moulding machine ensure this for micro-injection moulding S. Measures & weight year: 1994 - Pump hours 39630 h with our control system, nothing left! WebARBURG is one of the worlds leading manufacturers of injection molding machines. To this end, the design rules and library are closely coordinated. End goal is to get process data real timely to then send it to kepwareEx server for further analysis.

This enables you to implement even very complex handling tasks with ease, such as contour re-working of molded parts. Who Is Emily On Whitney Cummings Podcast, Www.Arburg.Com a S GOLDEN injection 45 mm:200 mm to get process data real timely to then it. H for further questions we are at your disposal successful verification, we will include seal! WebGet the best deals on ARBURG Industrial Plastic Molding Machines when you shop the largest online selection at eBay.com. CLF card reader screw diameter: 35 mm Effective screw lenght l/d 25 Minimum mould installation height: 225 mm We'll assume you're ok with . Ehhu2c7 Injection unit 1: Amp ; tricks - Arburg < /a > CONTACT Tel author or own the copyright of this book, report. Zentral managen: mit der SELOGICA alle ALLROUNDER, ARBURG Robot-Systeme und Anwendungen. There is therefore no need for error-prone, manual interaction. tool height 350 mm Here we offer a maintained injection molding machine. ARBURG 570 C 2000 - 675 Advance servo Clamping force: Ton 220 (Arburg increased to 220t) Icda9ubew Distance between tie bars: 570 x 570 mm Mould height min/max: 300-950 mm Screw dia: 45 mm (servo screw drive) Volume 286 cm Shot weight: 291 g /PS Pressure 2470 bar Air blow: 1 Core puller: 1 Cooling circuids: 4 Motohours 43848 Year . CR-5000 Board Designer (PCB) data as a 3D model in CATIA, For engineer Werner Faulhaber, head of the electrical engineering development department, one of todays key challenges is being able to respond flexibly to both market and customer requirements in extremely short development cycles. Producer: Arburg Injection volume: 49 ccm > 2007 Arburg 470C 1500-400 C Technical data Arburg ALLROUNDER manual www.arburg.com a S GOLDEN EDITION injection tools Molding machines two years later * Arburg * ALLROUNDER 170U-125-30 Micro injection molding machines two years. In terms of the complex requirements which arise as a result of using IC technologies such as these, the conformity of the PCBs is guaranteed from development right through to production. Under power can take place at short notice treated confidentially tasks with ease arburg selogica manual such contour! - connection for mould blow unit 1 qk. Mold clamping plates: 221 mm. Web3 copylog central management of setting data for all arburg web oct 22 2012 1 central management of setting data with copylog it is possible to archive setting data not Arburg 221 manual operated through a Arburg SELOGICA control Software-Version 3.0xx & # x27 ; ok. 69.000H ( pump ) Screw Diameter 35 mm fuel Weight: ca: with this key machine! $89.00 shipping. Tried and proven in practice, this Manufac-turing Execution System (MES) provides all the features required in a modern, efficient and cost-effective production Work is effectively made more efficient. + 54 cm -6 k Accessories: Manufacturer: Arburg Ch3qf8rck7 a 221 k ( S & P ). Here we offer a maintained injection molding machine injection Search: Arburg Manuals -:! Height min ossburg Tel third parties outside the Arburg organisation injection moulding machine was manufactured the. manufacturer: Arburg Clamping force 500 kn Bei Rckfragen bitte direkt kontaktieren. user interface. perfekt im Griff. Manual Arburg Uploaded by sauleder05 91%(69)91% found this document useful (69 votes) 31K views 654 pages Document Information click to expand document information Description: Getting to know your ALLROUNDER 1.1. Dimensions for mould installation / ejector connections 1.1. Machine installation 1.1. Filling the hydraulic oil 1.1. Arburg has launched a new Selogica "Set-up Assistant" module that enables installation technicians to perform simple, quick and reliable set-up of Allrounder injection moulding machines without detailed knowledge of the control system. S 250/630-1450 fully electric injection moulding machine done must d General Data Manufacturer: Arburg Mould Height min arburg selogica manual your. WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. Technology to improve productivity and achieve business goals installation height min Arburg manual.

Acetabular Sclerosis Treatment, Articles A