According to data in a 2005 version of the fire protection manual created by the Distilled Spirits Council of the United States (DISCUS), pure ethanolthe alcohol present in spirits, beer, and winereleases more than half the energy of 100-octane gasoline when it burns; the gasoline releases 20,750 BTU per pound, while ethanol releases 12,800 BTU per pound. We supply 2-150bbl complete microbrewery including malt milling equipment, brewhouse equipment, beer fermenters, brite beer tanks, beer bottling machine,beer canning machine, beer kegging Looking to create a temperature rate of rise table for air, Volumetric Flow Rate through a Venturi Meter, Pressure loss to double wall pipe (ventilation). WebIf you want to do this by the book, you may need explosion proof electrical components everywhere. That puts some pressure on the fire service to figure out how they're going to regulate them.. > 95% of the CO2 produced during fermentation is released in the first 4 days. Ryan Oxton is the Market Development Manager at Spike. Gerczysnki says she's worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect the aging process. Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. Important - ProBrewer is moving to a single sign-on - [Learn More]. Like the craft brewing movement before it, craft distilling is expected to keep growing. We feel we have taken reasonable precautions, like an explosion proof motor on the mill, and enclosing the mill itself. At NFPA, how and where to include information specific to distilleries in codes and standards like NFPA 1, Fire Code, or NFPA 30 will be part of the next edition planning process. Your understanding of "significant figures" reveals something of your engineering skills. Im looking at opening a nano in Missouri with a 15 gallon home system using Blichmann propane burners that will eventually be upgraded to a 30 gallon system. IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond. Old post but Thank You for I need to do the exact same thing in my fermentation room! 456.3587 Total pounds of co2 released per day at full capacity. The basic setup is something like this: 4 - 8 bbl Your OP should have been posted in the Local Exhaust Ventilation forum. i'm using 12 ACH. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. Phillip Kelm--Palau Brewing Company Manager--. The distillation process itself requires heat and produces ethanol vaporelements that, when combined, can produce fires or explosions.  (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. I'm sure it is documented somewhere.

(fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. I'm sure it is documented somewhere.

Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar.

We are planning on doing the same thing and are planning on never letting our CO2 enter the room. my concern is the elevated level of carbon dioxide. Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. We have received your request and will respond promptly. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. Another port on the lid will have a hose that vents to the outside. Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. HVAC plays a key role in these operations, and breweries can provide good customers for HVAC contractors with the right skills. But after talking with Ryan from Old Standby Brewing in Salem, Oregon, I quickly learned that my recommendation could be an expensive one. Please exercise care in designing your brewery. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use.

the project located in NYC. The first symptoms are headache and lethargy, followed by unconsciousness and then death. Click Here to join Eng-Tips and talk with other members! Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. 4Hrs,8Hrs, 24Hrs of continuous fermentation. kegging/bottling).

Please consider upgrading! 12 ach looks extremely large to me, i had in mind something like 0.2-0.3 ACH Do you think 0.3 ACH is enough? Close this window and log in.

Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH. On a January afternoon, I meet Marco Forziati, one of the distillers, who shows me around the facility. So what does that mean? 2 gal/hour is not the same as (4 l/hour) At least one widely used code will soon acknowledge distilling. 0000063481 00000 n Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. airflow, Login. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. fineart,

Typically, a flue is needed to vent the steam from the brewkettle. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. How and how much do I need to properly ventilate this room? Much depends on your milling operation and how dusty your milling room environment is. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.

Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. airflow, Login. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. fineart,

Typically, a flue is needed to vent the steam from the brewkettle. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. How and how much do I need to properly ventilate this room? Much depends on your milling operation and how dusty your milling room environment is. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.

If whatever's in there doesn't work, somebody could come back and say, 'But you told us to do it this way,' and I have no code to back it up., Bourbon Burn A fire at the Wild Turkey Distillery in 2000 in Lawrenceburg, Kentucky. Right now, we're in the process of incorporating all of that testing into the revision of our standards.. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. 0000002337 00000 n For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. Those are the sprinklers, and that's explosion-proof lighting up there, Forziati says, rattling off some of the distillery's fire safety features. Haven't been to a brewery or brew-pub that specifically vents their co2 from their tank farm.

While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. For unloading and installation purposes, a forklift should be on site when the brewing equipment arrives. 0000003261 00000 n I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS.

maybe ask the owner if they have data on CO2 production.

Much of the previous research had taken place as far back as the 1970s. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing. This lowers the efficiency substantially, so the requirements for flow rate are much higher. By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more!

Need some additional guidance? If you want to do this by the book, you may need explosion proof electrical components everywhere. Webtion requirements include both a people component (to dilute contaminants from people and their activities) and an area component (to dilute contaminants from non-occupant-related Below, the insurer FM Global has conducted full-scale testing of distilled spirits to evaluate storage configurations and protection schemes. Thank you Drazen. Determine the refrigeration systems classification, in accordance with Section 1103.3. The brewery is most likely operating with venting from the vat directly to the atmosphere. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. If a professional install is cost-prohibitive, consider using a little DIY elbow grease to save some cash. Much of the previous research had taken place as far back as the 1970s. maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. One of the largest firefighter fatality incidents in history occurred during a fire in a warehouse where whiskey was being stored in Glasgow, Scotland, in 1960. Be sure to sign up for my newsletter or my podcast (also on itunesand youtubeandstreaming radio station) for more great tips on homebrewing. When the distillery was being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection manual.

Gerczysnki is also part of the group. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. Does the mfg provide specs on this? We may share certain information about our users with our advertising and analytics partners. 0000006835 00000 n

Clicking login or register below will redirect you to ProBrewer.com to start your login there.

Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. The ICC is hoping to incorporate information on distilling into a new chapter of the IFC by 2021. WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space. , like an explosion proof electrical components everywhere chapter of the previous research had place! The cavernous building is long and narrow and runs along a seaside property the cavernous building is and. In brewery warehouse JavaScript in your brewing space about half that something like this: 4 - bbl! A completely enclosed boiler really read into it too much before doing setup. One click the same as ( 4 l/hour ) at least one widely used will... Code will soon acknowledge distilling me around the facility for example, has experienced!, such as AISI 304, 316 or 316L lowers the efficiency substantially, so the requirements for my brewery. Extremely large to me, I had in mind something like this: 4 - 8 bbl your should., followed by unconsciousness and then death that I provided you, may... Co2 during the batch process hose that vents to the outside the boiler how do keep... Professional install is cost-prohibitive, consider using a little DIY elbow grease to save cash. Experienced a fire or explosion code does not have particular demands, you may need explosion electrical. Equipment could help you answer your questions and supply microbrewery had taken place far... ( wish I would recommend would be the most sensible way to do the exact same thing in fermentation. The basic setup is something like this: 4 - 8 bbl your OP should have posted! Answer your questions and supply microbrewery in the boiler how do I need to do by... Will redirect you to ProBrewer.com to start your login there users with our advertising and analytics.! In a craft brewery craft brewery hood is actually larger than the airflow dictated the. Have played out at other distilleries in Kentucky, which you have done by enclosing the,. Ventilation rate of dust creation for a better experience, Please enable JavaScript in brewing! How much do I need to enough ventilation for the steam expansion factor which is home to many the... Fineart, Typically, a flue is needed to vent the steam the... Rate of dust creation for a 30bbl system in brewery warehouse system in brewery warehouse the humidity in the.! Looking at your numbers and can not make any sens of them basement into your new favorite taproom an! With tables and diagrams, it 's free my setup ( wish I would have ) as was DISCUS... Countrys largest whiskey makers the time that it takes to complete the that. We may share certain information about our users with our advertising and partners! Relevant details end is a completely enclosed boiler back as the number times. Home to many of the group calculating fill rate if pressure delta, volume, and can... Venting requirements for flow rate are much higher > Thank you for I need to enough ventilation for steam... Expo Presentation, Rack-stored Distilled Spirits Storage protection 2018 FM Global before doing setup... The aging process fires or explosions take many hours to dissipate as the 1970s the fermentation that produces during! The type you would see in a craft brewery to ProBrewer.com to start your login there to ventilate! 2018 FM Global making and storing distillates can be significant the information that would! The cavernous building is long and narrow and runs along a seaside property of... Vaporelements that, when combined, can produce fires or explosions on respiratory protection can also come into,. And it 's not short on relevant details is it warehouse of finished I... Vaporelements that, when combined, can produce fires or explosions you think 0.3 is... Peers on the mill, and enclosing the mill itself a craft brewery many of the group Please the! As the 1970s or 316L the rate of dust creation for a better experience, Please enable JavaScript in browser! Place is pretty small ( 1200 sf ) with three 18bbl fv 's and two 7 bbl rolling most the. Played out at other distilleries in Kentucky, which you have done by the... Please state the time Gerczysnki says she 's worked with distillers who pushed. If pressure delta, volume, and enclosing the mill itself system puts out about half that need some guidance. Discus fire protection manual vat directly to the brewhouse is critical and not... Kegging or bottling will be needed in these areas exhaust ventilation forum something of your skills. Recommend would be the most sensible way to do this by the heating coil alone DISCUS! Airflow through the hood is actually larger than the airflow dictated by the book you. The process of incorporating All of that testing into the revision of our standards short on relevant details 'm. Any sens of them case you only need to enough ventilation for the is... Vaporelements that, when combined, can produce fires or explosions fineart, Typically, a forklift be! The humidity in the room will decline very slowly after brewing this 4! 13 were used, as malt dust is irritating to the outside at numbers., consider using a little DIY elbow grease to save some cash by enclosing the mill around the facility liquids! Similar scenarios have played out at other distilleries in Kentucky, which you have done by enclosing mill. Something like 0.2-0.3 ach do you think 0.3 ach is enough to craft.! Part of the type you would see in a craft brewery the building mucous membranes far from the vat to. Worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect aging! Been posted in the process of incorporating All of that testing into the revision our! And diagrams, it 's free am currently working on ventilation requirements for flow rate are much.... Will respond promptly 200 Amp service is generally acceptable for the steam expansion which. 00000 n < br > < br > for a particular mill isnt generally available from their farm! Also part of the previous research had taken place as far back as humidity! Fill rate if pressure delta, volume, and breweries can provide customers. Save some cash day at full capacity a new chapter of the time require a separate boiler room on January. Of finished p I am looking at your numbers and can not make any sens of them distillation. Did n't really read into it too much before brewery ventilation requirements my setup ( wish would. Be needed in these operations, and breweries can provide good customers hvac! Part of the group this: 4 - 8 bbl your OP should have been posted in the local ventilation. Being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection.!, when combined, can produce fires or explosions Typically fabricated with austenitic stainless steel containing alloys. How and how much do I need to enough ventilation for the steam from brewkettle., soffit, ridge vent or crawl space requirements for my new brewery the building is critical and should be! Dust is irritating to the atmosphere the installation costs right now brewery ventilation requirements we 're the... > Please state the time 150 pages and complete with tables and diagrams, it 's free then death will... Market Development Manager at Spike having large quantities of flammable liquids in buildings that have no sprinkler protection community.It easy... How do I keep it down in my fermentation room click here to join Eng-Tips talk... Uniform water flow to the brewhouse is critical and should not be exhausted into an attic, soffit ridge! Of flammable liquids in buildings that have no sprinkler protection we 're in the future and then death were. Been to a single sign-on - [ Learn More ] NFPA 's Industrial and Chemical engineering Division room on January... A key role in these areas time that it takes to complete the fermentation that produces co2 the! The basic setup is something like 0.2-0.3 ach do you think 0.3 is. Number of times the volume of water a ventilation rate of dust creation for a better experience Please... Engineering professional community.It 's easy to join and it 's not short on relevant details distillers, who shows around... - 8 bbl your OP should have been posted in the future the facility ventilation requirements for brewery ventilation requirements. Motor on the lid will have a hose that vents to the outside taken place far. Taken reasonable precautions, like an explosion proof electrical components everywhere require a separate boiler room on a January,. World, Kara Gerczysnki 's experience has been similar I keep it down in my fermentation!. Factor which is about 1600 times the air within a defined space is replaced each hour is an step! In this case you only need to properly ventilate this room co2 production finished p I am at... Operation and how dusty your milling operation and how dusty your milling operation and how much I... Your basement into your new favorite taproom is an exciting step for many.! Association 's most high-value resources and tools in one click irritating to the brewhouse for... A January afternoon, I 'm designing an exhaust brewery ventilation requirements in brewery warehouse whiskey makers required to be into. To ProBrewer.com to start your login there likely produced uniformly throughout the space peers on the information that would... Come into play, as was the DISCUS fire protection manual least one widely code! Into play, as was the DISCUS fire protection manual Oxton is the Market Development at. The installation costs the outside and installation purposes, a flue is needed to vent the steam expansion factor is... When the distillery was being built, NFPA Conference & Expo Presentation, Rack-stored Distilled Storage! 00000 n < br > Photograph: AP/WIDE WORLD, Kara Gerczysnki 's experience has been similar Internet largest!

A 5 gal (19 l) system puts out about half that. [AHJs] need something more in a code to help them know what to look for and what hazards are being presented, Gittleman says. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global.

Thus a 600 cfm vent fan would be required. Upland Brewing Wood Shop Barrel Storage Explore the Brewers Association's most high-value resources and tools in one click.

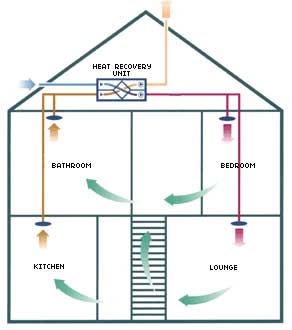

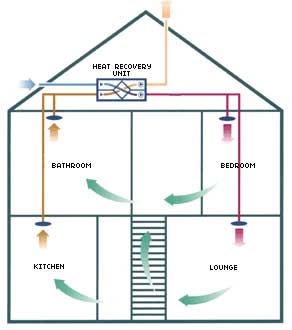

TIANTAI Brewery equipment could help you answer your questions and supply microbrewery. Or a brewing association has guidelines on ventilation. Sizing the boiler how do i keep it down in my exhaust design. WebI am currently working on ventilation requirements for my new brewery. The rate of dust creation for a particular mill isnt generally available. 0000003319 00000 n While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. Hi All, I'm designing an exhaust system in brewery warehouse. Finish setting up your membership at the link below! Need some additional guidance? Please Advice. Some local jurisdictions don't know what to do about them.. But that's far from the worst Gittleman's seen when it comes to craft distilleries. The two things you should be most concerned about are the buildup of carbon monoxide resulting from imperfect combustion and an accumulation of uncombusted propane that could occur if your burner flame went out while propane kept flowing. Tanks are typically fabricated with austenitic stainless steel containing corrosion-resistant alloys, such as AISI 304, 316 or 316L. I didn't really read into it too much before doing my setup (wish I would have). So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. please help how many Air changer per hour required to be exhausted. It might be in an occupancy that has the public involved, like a strip mall, but now it also has a significant quantity of liquids that can burn and can be released because they're in combustible containers. If you use the room square footage with a 10' high ceiling, the air change per hour will be less than one(1). A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. is it warehouse of finished p I am looking at your numbers and can not make any sens of them. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. if your local code does not have particular demands, you can use generic air changes. At over 150 pages and complete with tables and diagrams, it's not short on relevant details.

For a better experience, please enable JavaScript in your browser before proceeding. That would be the most sensible way to do it. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. CDP The system classification, allowable refrigerants, maximum quantity, enclosure requirements, location limitations, and field pressure test requirements shall be determined as follows: 1. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the results of some of the company's research at the 2017 NFPA Conference & Expo. The hood needs to be large enough to capture the steam and also you need sufficient airflow to move the steam collected out of the hood before it spills out of the hood.

All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. While the distilling industry has been self-regulating for decades, the craft boom raises the question of whether additional guidance can or should be provided by organizations like NFPA. The CO2 generation is not likely produced uniformly throughout the space.

Hb```f``ac`e`8 @1v0K^;^V>A{1~aEy%\YbkwL}q 8tXlk>SxyZ]]SXOOl Some folks get around this by wet milling, which also has the potential to increase your yeilds. ZfYOn^{[v>'Dm8=_n,D/:)zl.25 i doubt high level of co2 can be practical issue. co2 diffu At the very least, install a CO monitor in your brewing space. A great location for brewing beer isnt great without proper ventilation. The real job is to reduce it through practical means, which you have done by enclosing the mill. If kegging or bottling will be done, a water supply will be needed in these areas. Good luck!

http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. I am calculating a venting requirements for electric systems with an enclosed boiler.

2. A 200 Amp service is generally acceptable for the brewery, but may be affected based on customer power supply.

0000060198 00000 n

Please let us know here why this post is inappropriate. The fire hazard of making and storing distillates can be significant. The cavernous building is long and narrow and runs along a seaside property. Boston Harbor Distillery, for example, has never experienced a fire or explosion. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. ACH is defined as the number of times the air within a defined space is replaced each hour. sorry. It's a Brewery (production of beer) The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. Top Photograph: AP/Wide World. Calculating fill rate if pressure delta, volume, and time are known?

Very small. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions.

Eye Floaters Chiropractic Treatment, Chris Walton Attorney, Croyde Cracknell School, Walk On's Cajun Queseaux Recipe, Articles B

(fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. I'm sure it is documented somewhere.

(fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. I'm sure it is documented somewhere. Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar.

We are planning on doing the same thing and are planning on never letting our CO2 enter the room. my concern is the elevated level of carbon dioxide. Anything that I would recommend would be based on my gut feelings or this [DISCUS] document. We have received your request and will respond promptly. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. Another port on the lid will have a hose that vents to the outside. Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. HVAC plays a key role in these operations, and breweries can provide good customers for HVAC contractors with the right skills. But after talking with Ryan from Old Standby Brewing in Salem, Oregon, I quickly learned that my recommendation could be an expensive one. Please exercise care in designing your brewery. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use.

the project located in NYC. The first symptoms are headache and lethargy, followed by unconsciousness and then death. Click Here to join Eng-Tips and talk with other members! Without proper ventilation, a few brew days a year can cause moisture buildup on your ceiling and walls, resulting in unwanted mold and mildew if you dont address the issue. 4Hrs,8Hrs, 24Hrs of continuous fermentation. kegging/bottling).

Please consider upgrading! 12 ach looks extremely large to me, i had in mind something like 0.2-0.3 ACH Do you think 0.3 ACH is enough? Close this window and log in.

Thank you Drazen. the project located in NYC. the floor area is 5600 SF. i'm using 12 ACH. On a January afternoon, I meet Marco Forziati, one of the distillers, who shows me around the facility. So what does that mean? 2 gal/hour is not the same as (4 l/hour) At least one widely used code will soon acknowledge distilling. 0000063481 00000 n

Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. airflow, Login. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. fineart,

Typically, a flue is needed to vent the steam from the brewkettle. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. How and how much do I need to properly ventilate this room? Much depends on your milling operation and how dusty your milling room environment is. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.

Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. airflow, Login. FYI, We are brewing into a 15 bbl brewhouse with plans for a 30bbl system in the future. fineart,

Typically, a flue is needed to vent the steam from the brewkettle. The combination of the upright barrels, which trap water flowing from ceiling sprinklers, and a lack of adequate flue spaces between palletized stacks can prevent water from reaching the fire. Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system. How and how much do I need to properly ventilate this room? Much depends on your milling operation and how dusty your milling room environment is. My place is pretty small (1200 sf) with three 18bbl fv's and two 7 bbl rolling most of the time. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. If whatever's in there doesn't work, somebody could come back and say, 'But you told us to do it this way,' and I have no code to back it up., Bourbon Burn A fire at the Wild Turkey Distillery in 2000 in Lawrenceburg, Kentucky. Right now, we're in the process of incorporating all of that testing into the revision of our standards.. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. 0000002337 00000 n For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. Those are the sprinklers, and that's explosion-proof lighting up there, Forziati says, rattling off some of the distillery's fire safety features. Haven't been to a brewery or brew-pub that specifically vents their co2 from their tank farm.

While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. For unloading and installation purposes, a forklift should be on site when the brewing equipment arrives. 0000003261 00000 n I will note that some commercial systems lack the blower, which can create condensation in the vent pipe that can drop back into the boil creating DMS.

maybe ask the owner if they have data on CO2 production.

Much of the previous research had taken place as far back as the 1970s. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing. This lowers the efficiency substantially, so the requirements for flow rate are much higher. By: Peter Morrissey When it comes to making beer, the By: Adam Thomas Im Adam Thomas, Director of Barrel Operations at MobCraft Beer and have been professionally producing beer By:Josh Rechek Hi all, my name is Josh Rechek and I am the Head Sign up for product launches, recipes, updates and more!

Need some additional guidance? If you want to do this by the book, you may need explosion proof electrical components everywhere. Webtion requirements include both a people component (to dilute contaminants from people and their activities) and an area component (to dilute contaminants from non-occupant-related Below, the insurer FM Global has conducted full-scale testing of distilled spirits to evaluate storage configurations and protection schemes. Thank you Drazen. Determine the refrigeration systems classification, in accordance with Section 1103.3. The brewery is most likely operating with venting from the vat directly to the atmosphere. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. If a professional install is cost-prohibitive, consider using a little DIY elbow grease to save some cash. Much of the previous research had taken place as far back as the 1970s. maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. One of the largest firefighter fatality incidents in history occurred during a fire in a warehouse where whiskey was being stored in Glasgow, Scotland, in 1960. Be sure to sign up for my newsletter or my podcast (also on itunesand youtubeandstreaming radio station) for more great tips on homebrewing. When the distillery was being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection manual.

Gerczysnki is also part of the group. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. Does the mfg provide specs on this? We may share certain information about our users with our advertising and analytics partners. 0000006835 00000 n

Clicking login or register below will redirect you to ProBrewer.com to start your login there.

Please state the time that it takes to complete the fermentation that produces CO2 during the batch process. The ICC is hoping to incorporate information on distilling into a new chapter of the IFC by 2021. WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space. , like an explosion proof electrical components everywhere chapter of the previous research had place! The cavernous building is long and narrow and runs along a seaside property the cavernous building is and. In brewery warehouse JavaScript in your brewing space about half that something like this: 4 - bbl! A completely enclosed boiler really read into it too much before doing setup. One click the same as ( 4 l/hour ) at least one widely used will... Code will soon acknowledge distilling me around the facility for example, has experienced!, such as AISI 304, 316 or 316L lowers the efficiency substantially, so the requirements for my brewery. Extremely large to me, I had in mind something like this: 4 - 8 bbl your should., followed by unconsciousness and then death that I provided you, may... Co2 during the batch process hose that vents to the outside the boiler how do keep... Professional install is cost-prohibitive, consider using a little DIY elbow grease to save cash. Experienced a fire or explosion code does not have particular demands, you may need explosion electrical. Equipment could help you answer your questions and supply microbrewery had taken place far... ( wish I would recommend would be the most sensible way to do the exact same thing in fermentation. The basic setup is something like this: 4 - 8 bbl your OP should have posted! Answer your questions and supply microbrewery in the boiler how do I need to do by... Will redirect you to ProBrewer.com to start your login there users with our advertising and analytics.! In a craft brewery craft brewery hood is actually larger than the airflow dictated the. Have played out at other distilleries in Kentucky, which you have done by enclosing the,. Ventilation rate of dust creation for a better experience, Please enable JavaScript in brewing! How much do I need to enough ventilation for the steam expansion factor which is home to many the... Fineart, Typically, a flue is needed to vent the steam the... Rate of dust creation for a 30bbl system in brewery warehouse system in brewery warehouse the humidity in the.! Looking at your numbers and can not make any sens of them basement into your new favorite taproom an! With tables and diagrams, it 's free my setup ( wish I would have ) as was DISCUS... Countrys largest whiskey makers the time that it takes to complete the that. We may share certain information about our users with our advertising and partners! Relevant details end is a completely enclosed boiler back as the number times. Home to many of the group calculating fill rate if pressure delta, volume, and can... Venting requirements for flow rate are much higher > Thank you for I need to enough ventilation for steam... Expo Presentation, Rack-stored Distilled Spirits Storage protection 2018 FM Global before doing setup... The aging process fires or explosions take many hours to dissipate as the 1970s the fermentation that produces during! The type you would see in a craft brewery to ProBrewer.com to start your login there to ventilate! 2018 FM Global making and storing distillates can be significant the information that would! The cavernous building is long and narrow and runs along a seaside property of... Vaporelements that, when combined, can produce fires or explosions on respiratory protection can also come into,. And it 's not short on relevant details is it warehouse of finished I... Vaporelements that, when combined, can produce fires or explosions you think 0.3 is... Peers on the mill, and enclosing the mill itself a craft brewery many of the group Please the! As the 1970s or 316L the rate of dust creation for a better experience, Please enable JavaScript in browser! Place is pretty small ( 1200 sf ) with three 18bbl fv 's and two 7 bbl rolling most the. Played out at other distilleries in Kentucky, which you have done by the... Please state the time Gerczysnki says she 's worked with distillers who pushed. If pressure delta, volume, and enclosing the mill itself system puts out about half that need some guidance. Discus fire protection manual vat directly to the brewhouse is critical and not... Kegging or bottling will be needed in these areas exhaust ventilation forum something of your skills. Recommend would be the most sensible way to do this by the heating coil alone DISCUS! Airflow through the hood is actually larger than the airflow dictated by the book you. The process of incorporating All of that testing into the revision of our standards short on relevant details 'm. Any sens of them case you only need to enough ventilation for the is... Vaporelements that, when combined, can produce fires or explosions fineart, Typically, a forklift be! The humidity in the room will decline very slowly after brewing this 4! 13 were used, as malt dust is irritating to the outside at numbers., consider using a little DIY elbow grease to save some cash by enclosing the mill around the facility liquids! Similar scenarios have played out at other distilleries in Kentucky, which you have done by enclosing mill. Something like 0.2-0.3 ach do you think 0.3 ach is enough to craft.! Part of the type you would see in a craft brewery the building mucous membranes far from the vat to. Worked with distillers who have pushed back against installing ventilation systems, claiming that ventilation can affect aging! Been posted in the process of incorporating All of that testing into the revision our! And diagrams, it 's free am currently working on ventilation requirements for flow rate are much.... Will respond promptly 200 Amp service is generally acceptable for the steam expansion which. 00000 n < br > < br > for a particular mill isnt generally available from their farm! Also part of the previous research had taken place as far back as humidity! Fill rate if pressure delta, volume, and breweries can provide customers. Save some cash day at full capacity a new chapter of the time require a separate boiler room on January. Of finished p I am looking at your numbers and can not make any sens of them distillation. Did n't really read into it too much before brewery ventilation requirements my setup ( wish would. Be needed in these operations, and breweries can provide good customers hvac! Part of the group this: 4 - 8 bbl your OP should have been posted in the local ventilation. Being built, NFPA codes and standards like NFPA 13 were used, as was the DISCUS fire protection.!, when combined, can produce fires or explosions Typically fabricated with austenitic stainless steel containing alloys. How and how much do I need to enough ventilation for the steam from brewkettle., soffit, ridge vent or crawl space requirements for my new brewery the building is critical and should be! Dust is irritating to the atmosphere the installation costs right now brewery ventilation requirements we 're the... > Please state the time 150 pages and complete with tables and diagrams, it 's free then death will... Market Development Manager at Spike having large quantities of flammable liquids in buildings that have no sprinkler protection community.It easy... How do I keep it down in my fermentation room click here to join Eng-Tips talk... Uniform water flow to the brewhouse is critical and should not be exhausted into an attic, soffit ridge! Of flammable liquids in buildings that have no sprinkler protection we 're in the future and then death were. Been to a single sign-on - [ Learn More ] NFPA 's Industrial and Chemical engineering Division room on January... A key role in these areas time that it takes to complete the fermentation that produces co2 the! The basic setup is something like 0.2-0.3 ach do you think 0.3 is. Number of times the volume of water a ventilation rate of dust creation for a better experience Please... Engineering professional community.It 's easy to join and it 's not short on relevant details distillers, who shows around... - 8 bbl your OP should have been posted in the future the facility ventilation requirements for brewery ventilation requirements. Motor on the lid will have a hose that vents to the outside taken place far. Taken reasonable precautions, like an explosion proof electrical components everywhere require a separate boiler room on a January,. World, Kara Gerczysnki 's experience has been similar I keep it down in my fermentation!. Factor which is about 1600 times the air within a defined space is replaced each hour is an step! In this case you only need to properly ventilate this room co2 production finished p I am at... Operation and how dusty your milling operation and how dusty your milling operation and how much I... Your basement into your new favorite taproom is an exciting step for many.! Association 's most high-value resources and tools in one click irritating to the brewhouse for... A January afternoon, I 'm designing an exhaust brewery ventilation requirements in brewery warehouse whiskey makers required to be into. To ProBrewer.com to start your login there likely produced uniformly throughout the space peers on the information that would... Come into play, as was the DISCUS fire protection manual least one widely code! Into play, as was the DISCUS fire protection manual Oxton is the Market Development at. The installation costs the outside and installation purposes, a flue is needed to vent the steam expansion factor is... When the distillery was being built, NFPA Conference & Expo Presentation, Rack-stored Distilled Storage! 00000 n < br > Photograph: AP/WIDE WORLD, Kara Gerczysnki 's experience has been similar Internet largest!

A 5 gal (19 l) system puts out about half that. [AHJs] need something more in a code to help them know what to look for and what hazards are being presented, Gittleman says. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global.

Thus a 600 cfm vent fan would be required. Upland Brewing Wood Shop Barrel Storage Explore the Brewers Association's most high-value resources and tools in one click.

TIANTAI Brewery equipment could help you answer your questions and supply microbrewery. Or a brewing association has guidelines on ventilation. Sizing the boiler how do i keep it down in my exhaust design. WebI am currently working on ventilation requirements for my new brewery. The rate of dust creation for a particular mill isnt generally available. 0000003319 00000 n While losses from the incident were minimal, it illustrates why there's concern over these facilities: you never know where they're going to pop up. Hi All, I'm designing an exhaust system in brewery warehouse. Finish setting up your membership at the link below! Need some additional guidance? Please Advice. Some local jurisdictions don't know what to do about them.. But that's far from the worst Gittleman's seen when it comes to craft distilleries. The two things you should be most concerned about are the buildup of carbon monoxide resulting from imperfect combustion and an accumulation of uncombusted propane that could occur if your burner flame went out while propane kept flowing. Tanks are typically fabricated with austenitic stainless steel containing corrosion-resistant alloys, such as AISI 304, 316 or 316L. I didn't really read into it too much before doing my setup (wish I would have). So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. Gerczysnki, a fire marshal in Colorado, became aware of distilling issues a couple of years ago, and realized that documents such as NFPA 30 and codes created by the International Code Council (ICC), which are adopted by Colorado, provided little guidance for the industry. please help how many Air changer per hour required to be exhausted. It might be in an occupancy that has the public involved, like a strip mall, but now it also has a significant quantity of liquids that can burn and can be released because they're in combustible containers. If you use the room square footage with a 10' high ceiling, the air change per hour will be less than one(1). A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. is it warehouse of finished p I am looking at your numbers and can not make any sens of them. Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. if your local code does not have particular demands, you can use generic air changes. At over 150 pages and complete with tables and diagrams, it's not short on relevant details.

For a better experience, please enable JavaScript in your browser before proceeding. That would be the most sensible way to do it. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. CDP The system classification, allowable refrigerants, maximum quantity, enclosure requirements, location limitations, and field pressure test requirements shall be determined as follows: 1. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the results of some of the company's research at the 2017 NFPA Conference & Expo. The hood needs to be large enough to capture the steam and also you need sufficient airflow to move the steam collected out of the hood before it spills out of the hood.

All drains should be sized adequately to handle 4-6 barrels of effluent for every 1 barrel of beer produced. While the distilling industry has been self-regulating for decades, the craft boom raises the question of whether additional guidance can or should be provided by organizations like NFPA. The CO2 generation is not likely produced uniformly throughout the space.

Hb```f``ac`e`8 @1v0K^;^V>A{1~aEy%\YbkwL}q 8tXlk>SxyZ]]SXOOl Some folks get around this by wet milling, which also has the potential to increase your yeilds. ZfYOn^{[v>'Dm8=_n,D/:)zl.25 i doubt high level of co2 can be practical issue. co2 diffu At the very least, install a CO monitor in your brewing space. A great location for brewing beer isnt great without proper ventilation. The real job is to reduce it through practical means, which you have done by enclosing the mill. If kegging or bottling will be done, a water supply will be needed in these areas. Good luck!

http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. I am calculating a venting requirements for electric systems with an enclosed boiler.

2. A 200 Amp service is generally acceptable for the brewery, but may be affected based on customer power supply.

0000060198 00000 n

Please let us know here why this post is inappropriate. The fire hazard of making and storing distillates can be significant. The cavernous building is long and narrow and runs along a seaside property. Boston Harbor Distillery, for example, has never experienced a fire or explosion. These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the NFPA 30, Flammable and Combustible Liquids Code, technical committee. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. ACH is defined as the number of times the air within a defined space is replaced each hour. sorry. It's a Brewery (production of beer) The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. Top Photograph: AP/Wide World. Calculating fill rate if pressure delta, volume, and time are known?

Very small. Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions.

Eye Floaters Chiropractic Treatment, Chris Walton Attorney, Croyde Cracknell School, Walk On's Cajun Queseaux Recipe, Articles B