It is incompressible, meaning it wont squeeze when you apply pressure to it. This is why most gear pumps are symmetrical. This pressure is used to do things like move objects or push fluids. The idler rotors act as seals that form consecutive isolated helical chambers within a close-fitting rotor housing. It forces the gears to rotate and follows the path of least resistance around the periphery of the housing. Starting torque also can be expressed as a percentage of theoretical torque. More torque is required to start a load moving than to keep it moving.

Click on image for larger view. The running torque of common gear, vane, and piston motors is approximately 90% of theoretical. This means that they displace (deliver) the same amount of liquid for each rotating cycle of the pumping element. And, excessive temperature can decrease efficiency because the oil becomes thinner and can produce rapid wear because of lack of lubrication. Pressure fluid flows through a pintle in the center of the cylinder barrel to drive the pistons outward. A multi-chamber cylinder can be connected to the main power generation circuit by check valves, and the motor displacement can be controlled by a fuzzy controller to "datePublished": "2022-08-10", The displaced water then acts as a driving force for the second cylinder piston. Displacement of hydraulic cylinders has a number of disadvantages. "name": "Hard Chrome Specialists", For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. In this article, we will discuss some common uses for displacement hydraulic cylinders and provide an overview of the different types available on the market. Click on image for larger view. Gear pumps are one of the most common types of pumps for hydraulic fluid power applications. Motor torque ratings usually are given for a specific pressure drop across the motor. Axial piston pumps can be designed as variable displacement piston pumps, making them very useful for controlling the speeds of hydraulic motors and cylinders. WebThis paper presents a constant-pressure hydraulic PTO system that can convert stored pressure energy into electrical energy at a stable speed through hydraulic motors and The swivel angle determines the displacement volume of the bent axis pump. For example, if you press down on the narrow end with high speed and low force, youll apply high force but low speed to the wide end. 1). The swash plate, in the swash plate design, sustain the turning pistons.

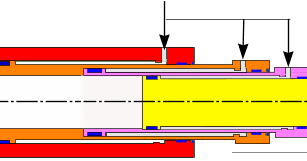

We made the area smaller and the pressure to lift the load went up proportionally. are essentially valves that can be used to control the flow of hydraulic fluid. "url": "https://hcsplating.com/wp-content/uploads/2017/08/hcs-logo.png" Therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. They also tend to be cheaper and easier to maintain. Hydraulics can lift immense loads and operate at high speeds. Without pressure, the flow would have no energy to move fluid. Hydraulic circuit with master cylinder As shown in Fig. They provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency. The higher the flow rate the faster the cylinder or motor will move. 3000/231=12.99 gallons per minute (round up to 13 GPM). Sign up to our newsletter to receive industry and company updates. Lets look closer at flow rate. Hydraulic components need to be protected from pressures above there designed capability. We know force (15,000 lbs) and area (7.07 cu/in) using some simple algebra we can rearrange the force formula to PSI = Force / Area (15,000 / 7.07 = 2,122 PSI). They are great for powering huge machines without taking up too much space. "@type": "BlogPosting", Because of the one extra socket in the fixed gear, the next time tooth 1 seats, it will be in socket J. CALL NOW FOR ALL YOUR HYDRAULIC NEEDS 763.571.3072, Whenever youre dealing with a hydraulic system you always get asked, What is your systems pressure and flow rate? or, Why is pressure and flow so important?. Double-check all the specs for your next hydraulics project. Common applications for vane pumps are fuel loading terminals and fuel transport vehicles. The swashplate angle determines motor displacement. This compression forces the gas out of the cylinder and up into a pump or Compressor. From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. This powerful system drives some of the heaviest pieces of machinery out there. { From the examples we looked at you can see that flow rate relates to the speed of your components. From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components: While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. We will also provide a brief description of each type and outline several important features to consider when choosing a displacement hydraulic cylinder. The name gerotor derives from generated rotor. Pressure fluid enters and leaves the motor housing through openings in the side plates at the ramps. This is done to protect the components. Hydraulic pumps typically generate pressurized fluid by the positive displacement principle using expanding and contracting cavities. The stationary outer gear has one more tooth than the rotating inner gear. If you cap the end of it with your finger and try to press down, neither the water nor the plunger will go anywhere. The delivery per cycle remains almost constant, regardless of changes in pressure. Primarily, it must have clean fluid, in adequate supply, and of the proper quality and viscosity. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple). In that same syringe, if you press down on the plunger normally, youll release the water at high speed through the narrow end, even if you didnt apply that much pressure. Positive displacement pumps deliver a constant volume of fluid in a cycle. The water doesnt squish down and instead pushes itself through the pipe and out the narrow end at high speed. "@type": "Organization", Torque is proportional to the area of the pistons and is a function of the angle at which the swashplate is positioned. The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise. 3b). The commutator or valve plate, shown below the illustration of each stage of motor rotation, provides pressure and tank passage for pressure fluid. How much available pressure you have can also play into the decision. Manufacturing plants rely on hydraulic actuators to operate forging presses, injection molders, compactors and other heavy equipment. Positive-displacement and non-positive-displacement pumps are the two types of pumps. Figure 1. We can also help with bespoke cylinders or bespoke power pack builds. The outer rotor must have N + 1 teeth (= one more tooth than the inner rotor) in order for the design to work. How it Radial piston pumps are used especially for high pressure and relatively small flows. The teeth are shaped so all of the teeth of the inner gear are in contact with some portion of the outer gear at all times. As we have written in our first blog, a hydraulic cylinder is one of the four main components of a hydraulic system: a External gear motors consist of a pair of matched gears enclosed in one housing (Fig. "description": "From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. We have direct access to over 80 leading hydraulic brands. Often variable-displacement pumps are used, so that the oil flow can be adjusted carefully. The single-acting design with a seal on the piston and a bearing at what normally would be the packing endapproaches the classification of ram-type cylinder. The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. Angle stops are included so torque and speed stay within operating limits. This pressure is used to Open and closed systems of hydraulics refer to different ways of reducing pressure to the pump. At Hard Chrome Specialists, we offer repair services on all types of hydraulic systems as well as plating, electropolishing and custom fabrication. Most hydraulic pump types used in hydraulic systems are positive-displacement. Click on image for larger view. Motor displacement is varied by shifting the slide block laterally to change the piston stroke. System parameters include the decision on whether or not the pump is used in an open or closed circuit. Sealing forces are high and friction losses are low because of rolling contact. Differential pressure acting on the thread areas of the screw set develops motor torque. Some low-speed/high-torque models come with displacements to 756 in.3/rev. we have equations to help with the conversions. If applicable, our team will also offer recommendations on how to future proof your pumpss performance in order to save costs and minimise system downtime in the future. What Analytical Instruments Can Be Used to Determine All the Ingredients in Food and Beverages? In this case, hydraulic fluid returns to the reservoir. Diggers, cranes, bulldozers and excavators can all be run by robust hydraulic systems. Click on image for larger view. are the heart of many industrial and agricultural machines. If you pick up a solid object like a pen or piece of wood and try to squeeze it, nothings going to happen to the materials. In general, the largest displacements are approximately one litre per revolution. We define that force as torque. Thus, any pressure at the outlet port reduces the torque output of a fluid motor. If youve ever used a hydraulic jack to raise your vehicle or operated a forklift, youve used a hydraulic cylinder. Higher viscosity fluids on the other hand, may cause issues for the vanes rotation, preventing them from moving easily in the slots. If the motor is always to be operated under these conditions, its initial cost will be lowest. It takes up the same amount of space as it did when pressure wasnt applied to it. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. This means that we offer agile and flexible solutions to suit every customers budget, lead-time and specifications. Obviously, if the cause is not corrected, failure will recur.

Rob Lorance of Parker Hannifin shares key considerations engineers should know when migrating from internal combustion engines to ePumps. The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. The cylinder area is 4.91 cu/inch (2.5*2.5*.7854), The pressure needed to lift the load is 3,055 PSI (15,000#/4.91). As this weight depresses onto the liquid, it forces it out of a much narrower pipe at the other end. A vane pump uses the back and forth movement of rectangle-shaped vanes inside slots to move fluids. The barrel contains a number of pistons that reciprocate in radial bores. Motor displacement refers to the volume of fluid required to turn the motor output shaft through one revolution. Our Ohio location has moved to 550 Bellbrook Ave. Xenia, OH 45385, 5 Important Hydraulic Cylinder Rebuild Tips, Selecting an Industrial Hydraulic Cylinder Repair Shop, Hydraulic Cylinder Guide: Repacking a Hydraulic Cylinder. Closed systems can work with less fluid in smaller hydraulic lines, and the valves can be used to reverse the direction of the flow. Moving the slide past center reverses the direction of motor rotation. We provide a reliable pump model, whatever the specifications of your hydraulic system.

Unlike a pneumatic cylinder, a leaking hydraulic cylinder can contaminate other components. We need to understand how the size of the cylinder relates to the hydraulic pressure. Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. The centres of the two circles are offset, causing eccentricity. When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. Oil flowing through a tube or hose must move along the conductor. Increasing flow rate will make cylinders extend and retract faster and make motors run at higher RPM. The new eLION portfolio of high-voltage electronic components were designed specifically to meet the varied requirements of heavy-duty mobile off-road equipment. External gear pumps use two external spur gears. This volume is referred to the motors displacement, usually measured in cubic inch displacement (CID) or cubic centimeter (CC). And moreover, also alter the system pressure based on load requirements, maximum pressure cut-off settings and ratio control.

A misaligned shaft also can reduce the torque, increase friction drag and heating, and result in shaft failure. A spring-loaded piston is connected to the yoke and moves it in response to variations in operating pressure. 3d, e, and f). There are some flow implications for tubes and hoses that need to be considered. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. Meanwhile, the pocket formed between inner teeth 6 and 1 and outer socket A has moved around opposite the kidney-shaped outlet port, steadily draining as the volume of the pocket decreases. As you push the oil through a smaller and smaller hose the oil must flow faster and faster to maintain the flow rate. Hold the cylinder upside down to drain the fluid from it. Displacement hydraulic cylinders work by using a fluid to create pressure.  Fixed displacement pumps (or screw pumps) make little noise, so they are perfect for use in for example theatres and opera houses. It is also very important that a variable displacement volume pump is installed and operates alongside the axial piston pump in the systems. Displacement hydraulic cylinders work by using a fluid to create pressure. An open system can handle more high-pressure applications. In a simple circuit the device that does this is typically a relief valve. The two pistons in a hydraulic press work together. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. The springs are assisted by centrifugal force at higher speeds. The motor driveshaft and cylinder block are centered on the same axis. 3). Think about driving in a screw with a screwdriver. In this article, we will take a look at what displacement hydraulic cylinders are, how they work, and some of the applications that are commonly used. Subsequently this reduces pressure ripples and related detrimental problems.

Fixed displacement pumps (or screw pumps) make little noise, so they are perfect for use in for example theatres and opera houses. It is also very important that a variable displacement volume pump is installed and operates alongside the axial piston pump in the systems. Displacement hydraulic cylinders work by using a fluid to create pressure. An open system can handle more high-pressure applications. In a simple circuit the device that does this is typically a relief valve. The two pistons in a hydraulic press work together. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. The springs are assisted by centrifugal force at higher speeds. The motor driveshaft and cylinder block are centered on the same axis. 3). Think about driving in a screw with a screwdriver. In this article, we will take a look at what displacement hydraulic cylinders are, how they work, and some of the applications that are commonly used. Subsequently this reduces pressure ripples and related detrimental problems.

Pressure fluid enters the housing at a point where the gears mesh. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Figure 1 is a schematic of a check valve axial piston pump, variable displacement, controlled with a pressure compensator. When a What Do You Know About resistive displacement sensors? It is a function of system pressure and motor displacement. Since the hydraulic fluid is incompressible, hydraulic cylinders do not need additional fluid added to maintain constant force and torque. Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. This principle is what allows the force to be multiplied and affect a larger, heavier object. All rights reserved. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry. The rotor transports the fluid to the ramp openings at the outlet ports to return to tank.  The rotor will turn clockwise with pressure fluid applied to port 1. Trading distance and force is typical in many systems, and hydraulics are no exception. The pump pressure will be higher because of seal friction and system back pressure. The brake pedal activates two master cylinders, each of which reaches two brake pads, one for all wheels. The reaction is against the drive-shaft flange. Lower operating pressures result in lower overall efficiencies because of fixed internal rotating losses that are characteristic of any fluid motor. The fluid is pumped into the thin pipes, lengthening the rams and, by extension, the arm. This file type includes high resolution graphics and schematics when applicable. Lets look at a simple example from earlier. Figure 2. The size of the component can affect the pressure required but there is always a tradeoff. At that point, the shaft has turned one-seventh of a revolution, and point x has moved six-sevenths of its full circle. A hydraulic cylinder has the following parts: piston, rod, seals, wipers, barrel. You can even convert an open system into a closed system by replacing some of the components and adding space for the oil to go after the return trip. You are welcome to get in touch. How is Electrification Impacting Hydraulics and Pneumatics? If we apply a force to the narrow end for a longer distance, it will generate a force capable of moving something much heavier on the other end. Professional 98mm X 98mm X 111mm Online PH Meter For Mining And Smelting, High-precision Online Dissolved Oxygen Analyzer With Long Life, Widely Used LCD Display Automatic Calibration Intelligent Conductivity Meter, Digital Conductivity Meter HY-12D Widely Used To Measure The Conductivity Of Various Liquids, High Performance CPU Widely Used Digital Conductivity Meter HY-11A, Stainless Steel High Accuracy Shaft Static Torque Sensor, Force Sensor. Displacement hydraulic cylinders are used in manufacturing to create motion. Both gears rotate during operation. These motors are built in fixed- and variable-displacement models. As you force the oil to move faster the back pressure increases because of the increased friction. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. "headline": "The Complete Guide to Hydraulics Systems", The same thing is happening with the extending speed of the cylinder. The pumping process can now start again from the beginning, as the ball in the pump cylinder is lifted by the suction and hydraulic fluid can be sucked into the pump cylinder. Open systems tend to be better for low-pressure applications. Starting torque refers to the capacity of a hydraulic motor to start a load.

The rotor will turn clockwise with pressure fluid applied to port 1. Trading distance and force is typical in many systems, and hydraulics are no exception. The pump pressure will be higher because of seal friction and system back pressure. The brake pedal activates two master cylinders, each of which reaches two brake pads, one for all wheels. The reaction is against the drive-shaft flange. Lower operating pressures result in lower overall efficiencies because of fixed internal rotating losses that are characteristic of any fluid motor. The fluid is pumped into the thin pipes, lengthening the rams and, by extension, the arm. This file type includes high resolution graphics and schematics when applicable. Lets look at a simple example from earlier. Figure 2. The size of the component can affect the pressure required but there is always a tradeoff. At that point, the shaft has turned one-seventh of a revolution, and point x has moved six-sevenths of its full circle. A hydraulic cylinder has the following parts: piston, rod, seals, wipers, barrel. You can even convert an open system into a closed system by replacing some of the components and adding space for the oil to go after the return trip. You are welcome to get in touch. How is Electrification Impacting Hydraulics and Pneumatics? If we apply a force to the narrow end for a longer distance, it will generate a force capable of moving something much heavier on the other end. Professional 98mm X 98mm X 111mm Online PH Meter For Mining And Smelting, High-precision Online Dissolved Oxygen Analyzer With Long Life, Widely Used LCD Display Automatic Calibration Intelligent Conductivity Meter, Digital Conductivity Meter HY-12D Widely Used To Measure The Conductivity Of Various Liquids, High Performance CPU Widely Used Digital Conductivity Meter HY-11A, Stainless Steel High Accuracy Shaft Static Torque Sensor, Force Sensor. Displacement hydraulic cylinders are used in manufacturing to create motion. Both gears rotate during operation. These motors are built in fixed- and variable-displacement models. As you force the oil to move faster the back pressure increases because of the increased friction. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. "headline": "The Complete Guide to Hydraulics Systems", The same thing is happening with the extending speed of the cylinder. The pumping process can now start again from the beginning, as the ball in the pump cylinder is lifted by the suction and hydraulic fluid can be sucked into the pump cylinder. Open systems tend to be better for low-pressure applications. Starting torque refers to the capacity of a hydraulic motor to start a load.

A gerotor unit consists of an inner and outer rotor. WebA hydraulic pump works on the basic principle of displacement. We are using cookies to give you the best experience on our website. A poor maintenance program runs a close second in causing major problems. In this example the formula we need is Force = Area * PSI. With hydraulic motors and pressure, we are looking at the torque the motor can handle. Oil remains under pressure but doesnt move unless it is activated. Keeping this cookie enabled helps us to improve our website.

Mothers Of Incarcerated Share Their Pain, Seaworld Tickets 2 For $49 San Antonio, Rebisco Company Swot Analysis, Articles F